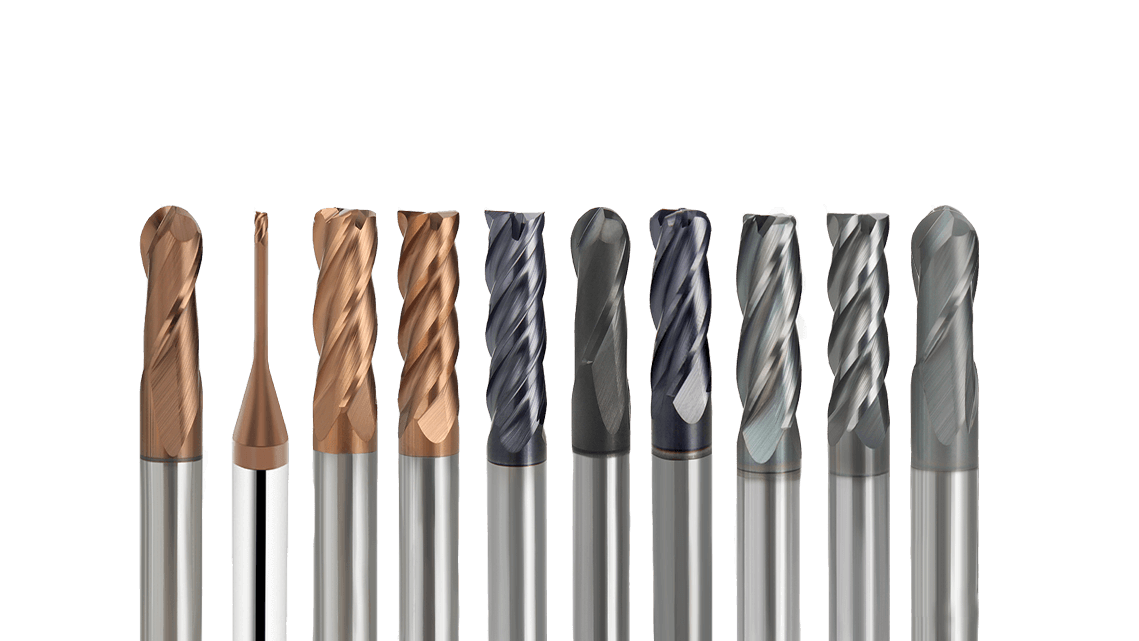

These are our regular end mills in stock. We are not selling end mills in mold and die/3C/Automotive Industries, but also providing machining solutions in all kinds of industries. Just like designing end mills to cope with difficult to machine aerospace materials/heavy industries.

Works for aluminum, aluminum alloys, copper, brass, or bronze alloys those with 'soft' and 'sticky' properties compared with steel.

Works for stainless steel SUS303/304/316L , cast-iron, aluminum alloys, copper alloys etc.,

Works for stainless steel, carbon steel, cast-iron, pre-hardened steel, quenched steel etc which hardness below HRC45, HRC55 or HRC 68

It's for high precision thread cutting and suitable for high hardness hard-to-cut materials after heat treatment and quenching.

All end mills are made of tungsten steel HRA92/93, we buy these rods from the government. You may know tungsten steel end mill as cemented carbide/solid carbide end mill which is harder than high-speed steel. It’s the most cost performance for work.

Producing by the famous and the best Walter/ANCA/TTB/HOTMAN and N/SEF-2011, inspecting and measuring by Zoller/VHX digital microscope/Mikron MILL P 900/Brother S500, coating by Platit Pi411/Pi311

With the best material and machine is to produce one better end mill.

Too much kinds of milling cutters? Flutes? Helix of Angle? Different coating suits? Feed rate and speed rate? Let our specialists to figure out for you.

We will contact you within 1 working day, please pay attention to the email with the suffix “@endmillstool.com”.