How to Choice An End Mill?

Workpiece Material and Hardness, Flutes, Types

Used for Aluminum Alloys/Copper/Wood/Plastic. Made by tungsten steel which is more wear resistant than high-speed steel and cobalt steel for the longest life and best finish.

| Type of End Mill | Ball Nose End Mills |

|---|---|

| Work for Workpiece | Aluminum Alloys, Copper, Plastic, Wood |

| Numbers of Flutes | 2 Flutes |

| Coating | Uncoating |

| Cutter Diameter | 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm |

| Nose Radius of Cut | 0.5mm, 0.75mm, 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm |

| Shank Diameter | 4mm, 6mm, 8mm, 10mm, 12mm |

| Overall Length | 50mm, 60mm, 75mm |

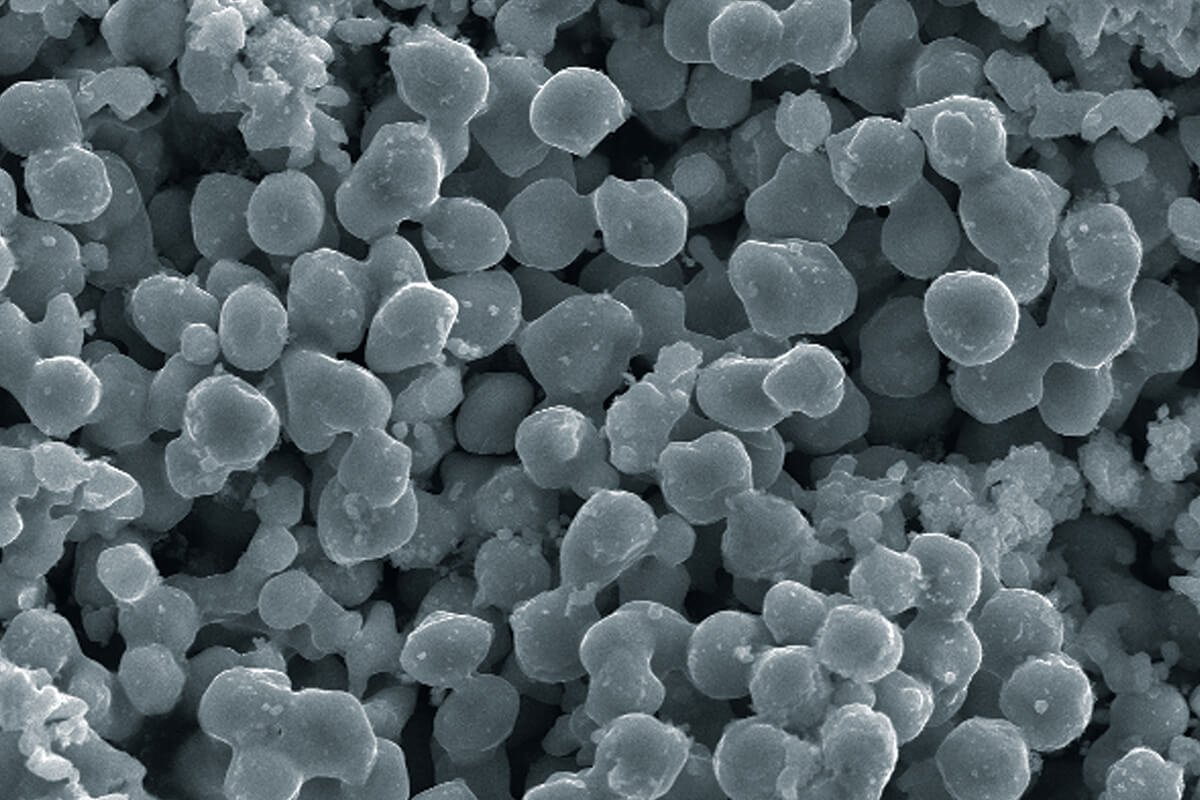

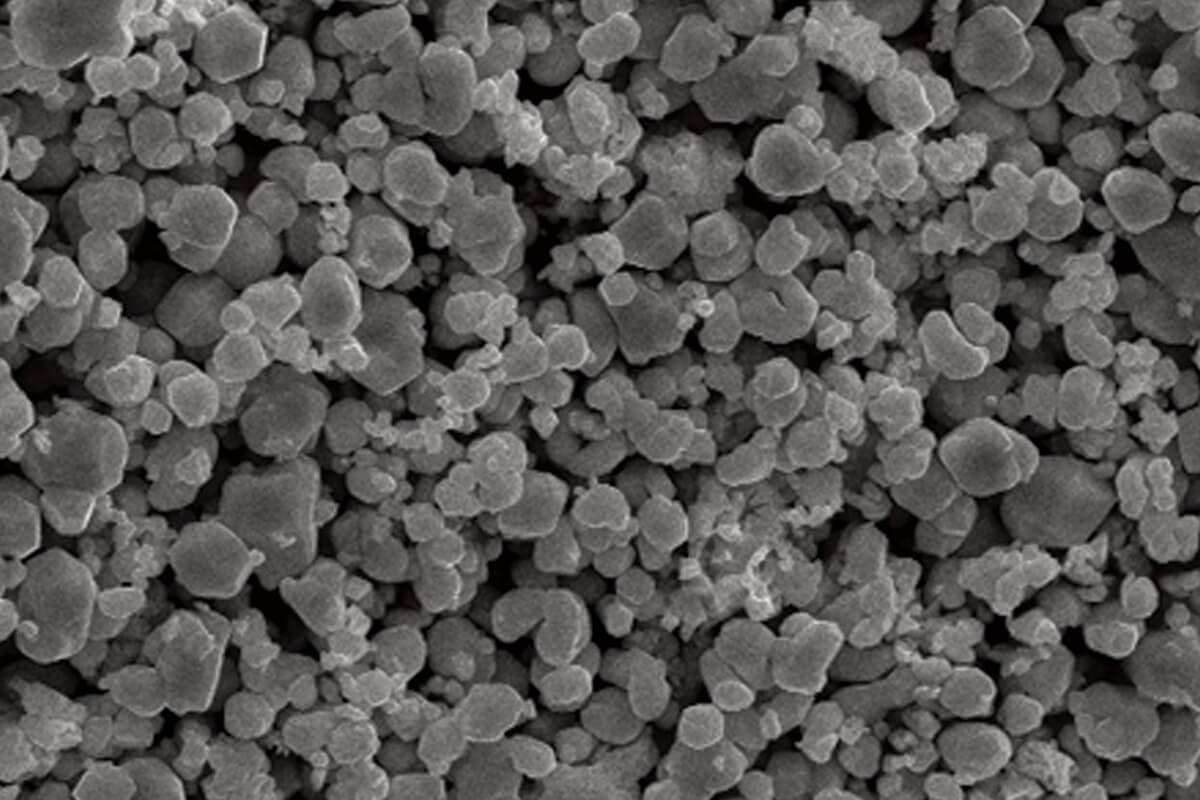

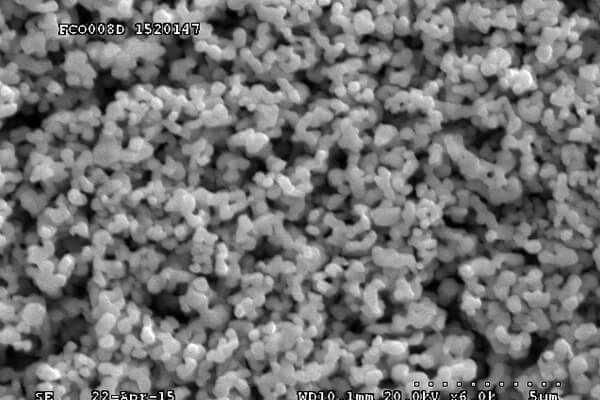

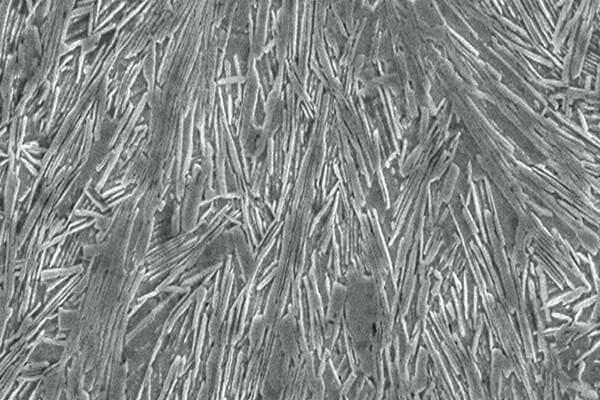

The raw material of rods are high quality tungsten powder, tungsten carbide, and cobalt powder. And they are produced bywith the latest manufacturing equipment and technologies.

Best equipments can produce much stabler milling cutters. Producing by Walter/ANCA/TTB/HOTMAN and N/SEF-2011, inspecting and measuring by Zoller/VHX digital microscope/Mikron MILL P 900/Brother S500, coating by Platit Pi411/Pi311

Let’s our end mills’ video.

OEM/ODM is welcomed, we have 40+ patents for our products.

Workpiece Material and Hardness, Flutes, Types

What’s An End Mill? End mill is a type of milling cutter to removing material from a given workpiece by a milling machine. It is