How to Choice An End Mill?

Workpiece Material and Hardness, Flutes, Types

Mainly used for continuous cutting of materials such as carbon steel, alloy steel, stainless steel, high temperature alloy materials, aluminium and other materials that produce continuous cutting. Discharge chips in the direction of shank. Used for blind holes.

| Type of End Mill | Thread Milling Taps |

|---|---|

| Work for Workpiece | Aluminum Alloys, Bakelite, Carbon Steel, Cast-Iron, Copper, Hard Plastic Fibreglass, Iron, Magnesium Alloys, Titanium Alloys, Zinc Alloys |

| Coating | Uncoating |

| Cutter Diameter | 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm |

| Thread Pitch | 0.4mm, 0.45mm, 0.5mm, 0.7mm, 0.8mm, 1mm, 1.25mm, 1.5mm, 1.75mm |

| Accuracy Class | RH4, RH5, RH6, RH7, RH8 |

| Length of Cut | 9mm, 11mm, 13mm, 16mm, 19mm, 22mm, 24mm, 29mm |

| Shank Diameter | 3mm, 4mm, 5mm, 5.5mm, 6mm, 6.2mm, 7mm, 8.5mm |

| Overall Length | 40mm, 44mm, 46mm, 52mm, 60mm, 62mm, 70mm, 75mm, 82mm |

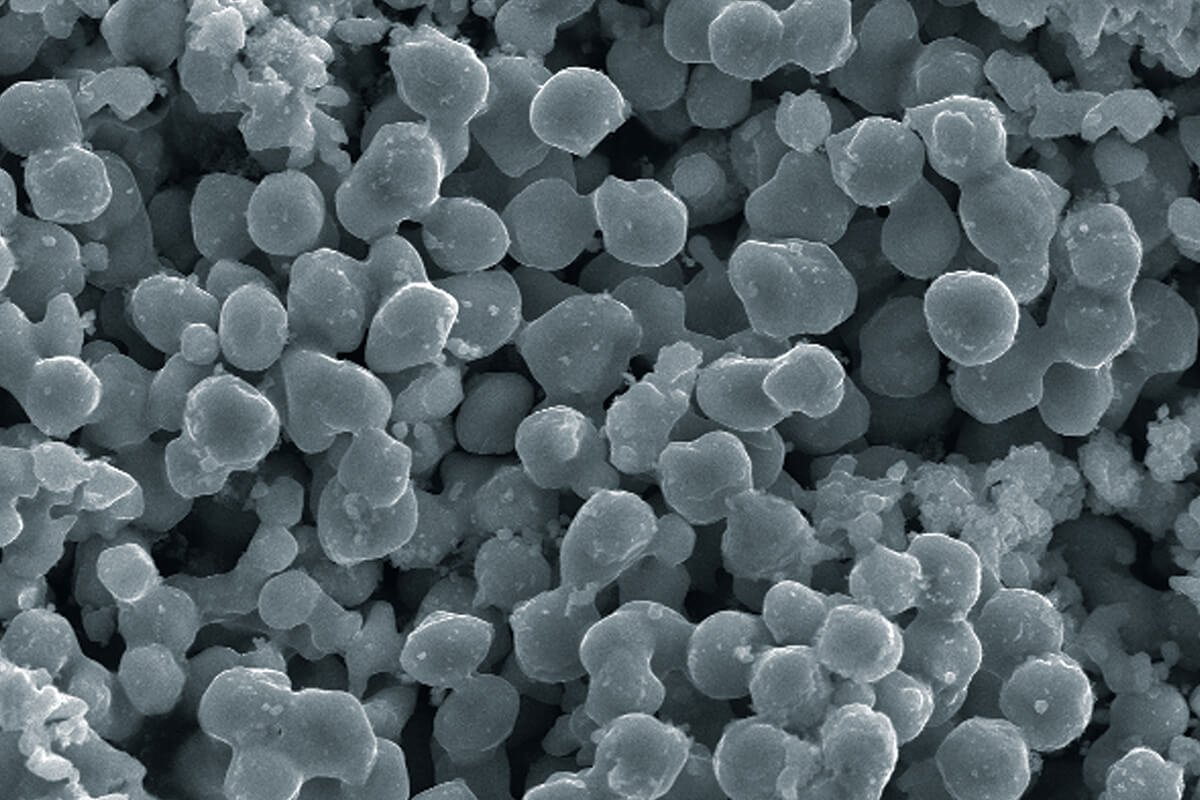

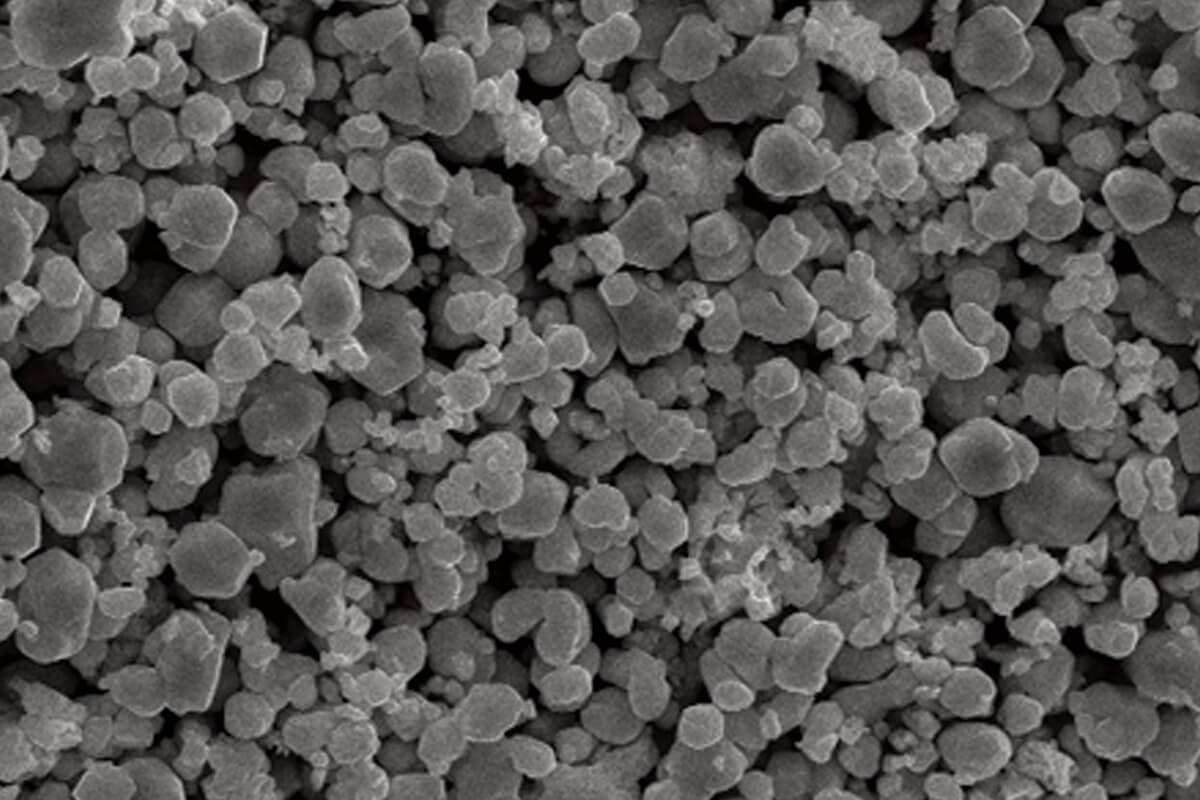

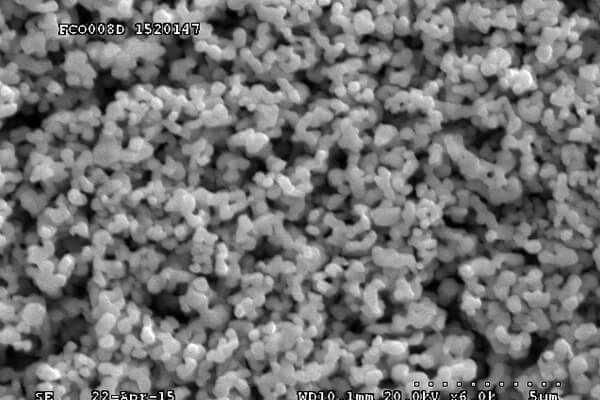

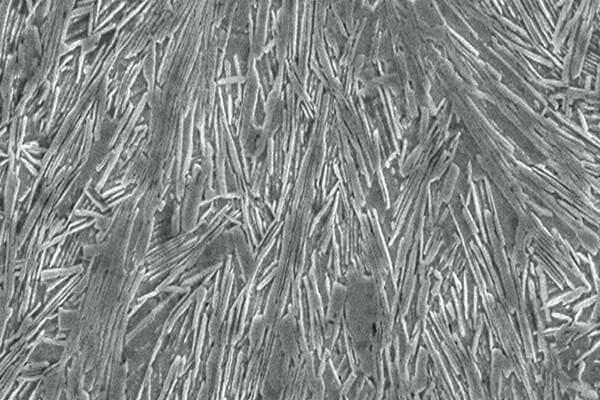

The raw material of rods are high quality tungsten powder, tungsten carbide, and cobalt powder. And they are produced bywith the latest manufacturing equipment and technologies.

Best equipments can produce much stabler milling cutters. Producing by Walter/ANCA/TTB/HOTMAN and N/SEF-2011, inspecting and measuring by Zoller/VHX digital microscope/Mikron MILL P 900/Brother S500, coating by Platit Pi411/Pi311

Let’s our end mills’ video.

OEM/ODM is welcomed, we have 40+ patents for our products.

Workpiece Material and Hardness, Flutes, Types

What’s An End Mill? End mill is a type of milling cutter to removing material from a given workpiece by a milling machine. It is